Excellence in quality and the flexibility that can respond even to the needs of high-mix low-volume production. A fusion of safety and efficiency that results in short turnarounds and low costs. This rock-solid production system is the result of our hard work. By using this integrated system, which includes consultation & ordering, design, prototyping, fabrication, assembly, and after-sales service, in addition to our proprietary factory automation system, we are able to meet customer requirements with cutting-edge logistics frames.

Process flow

Consultation & ordering Consultation & orderingFirst, we meet with the customer and carefully take note of their needs. We then decide on the specifications once we understand the purpose and characteristics of the products that will be placed in the frame. With these factors in mind, we are able to suggest an optimized product that is compatible with the customer's logistics systems and is easy to use on the production line. |

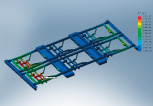

Design DesignBased on the drawing for the product that will be placed in the frame, we analyze it from various viewpoints such as efficiency, safety, and workability. We then work out the optimum shape and structure and use CAD to carry out a high-resolution stress analysis as well as dynamic simulations to design the ideal logistics frame. |

Prototyping PrototypingBased on the design diagram, we start fabricating prototypes. Skilled engineers intent on ensuring accuracy validate the assembly process and motion for each part and block. Any problems are fed back to Design immediately to keep quality as high as possible. |

Production ProductionOnce the prototyping process is complete and the specifications are confirmed with the customer, production process can start. A highly accurate automated line ensures that production efficiency and quality are maintained at a high level. We install equipment carefully considering safety-related factors. |

![]()

![]()

We have totally systemized our processes through technology such as our proprietary multi-spot welding system. Our production system is safe yet highly efficient, and is able to achieve short turnaround times.

Cutting |

Welding |

Painting |

Assembly |

Inspection InspectionDuring product processing, we carry out a stringent inspection at each step to check quality. Prototypes are subjected to strength, pressure, load, and transportation tests, etc. to ensure a high degree of safety, durability, and usefulness during transport. |

Shipping ShippingOnce the quality of the products is checked in the inspection and testing processes are finished, the products go to the shipping process. Based on the process plan, strict control of the product from shipment ensures that we can properly support our customers' production activities. |